ESTAN: A User-Friendly Toolbox for Improving Model Estimability and Predictive Performance

ESTAN is a user‑friendly modelling toolbox developed by Loughborough University in collaboration with CMAC’s Digital Manufacturing Research Centre. It simplifies complex sensitivity and estimability analyses, helping users build mathematical models and digital twins with stronger predictive performance.

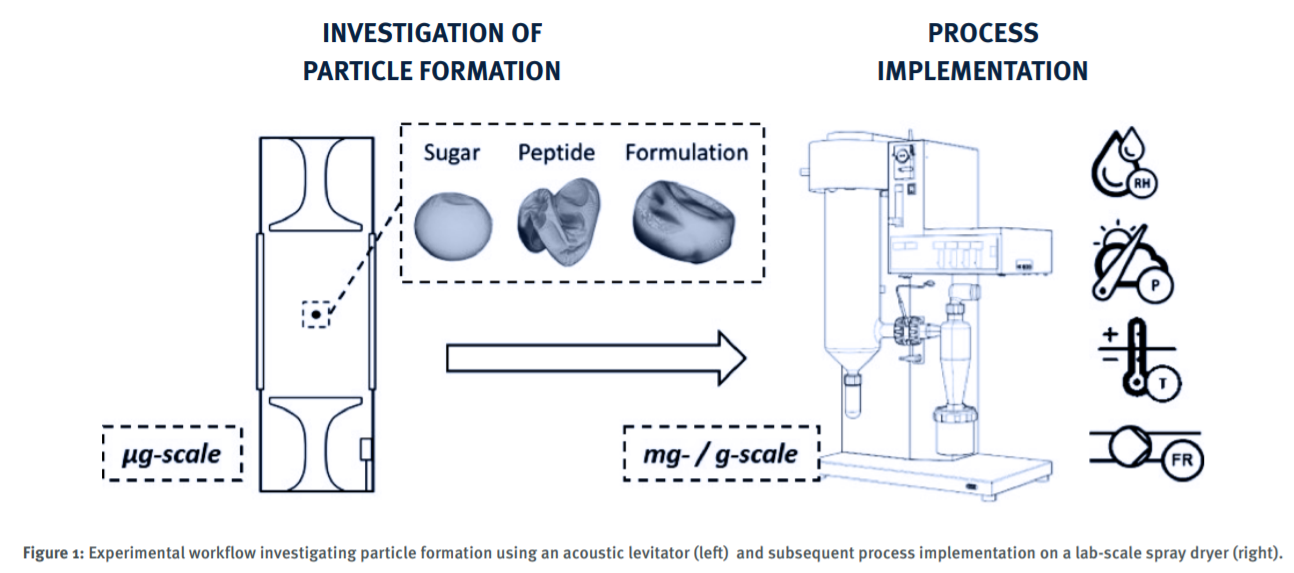

Digital Pharmaceutical Process Design: Faster, Cost Effective and Sustainable Delivery of Quality Drug Substance

Through digital-first process design, CMAC researchers decrease the material required for API development by an order of magnitude.

From Lab to Clinical Development: CMAC’s Impurity Rejection Workflow

Researchers at Eli Lilly & Company have successfully applied CMAC’s impurity rejection workflow in clinical development, achieving up to 100% rejection of problematic impurities.

Knowledge Transfer Partnerships

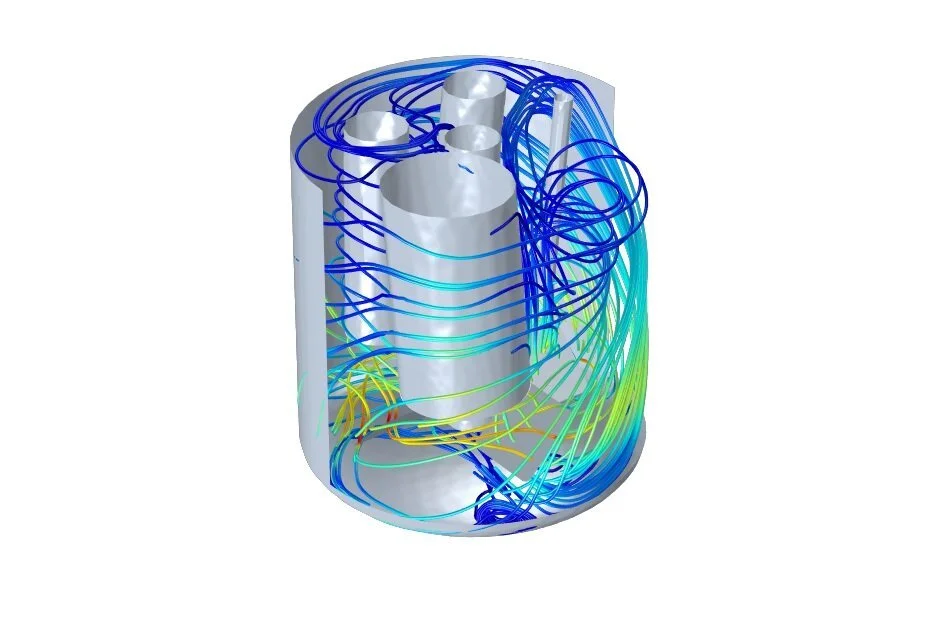

Model-based Digitalisation Framework Development for Continuous Manufacturing Processes

Workflows for the Application of a User-friendly Mechanistic Modelling Toolkit

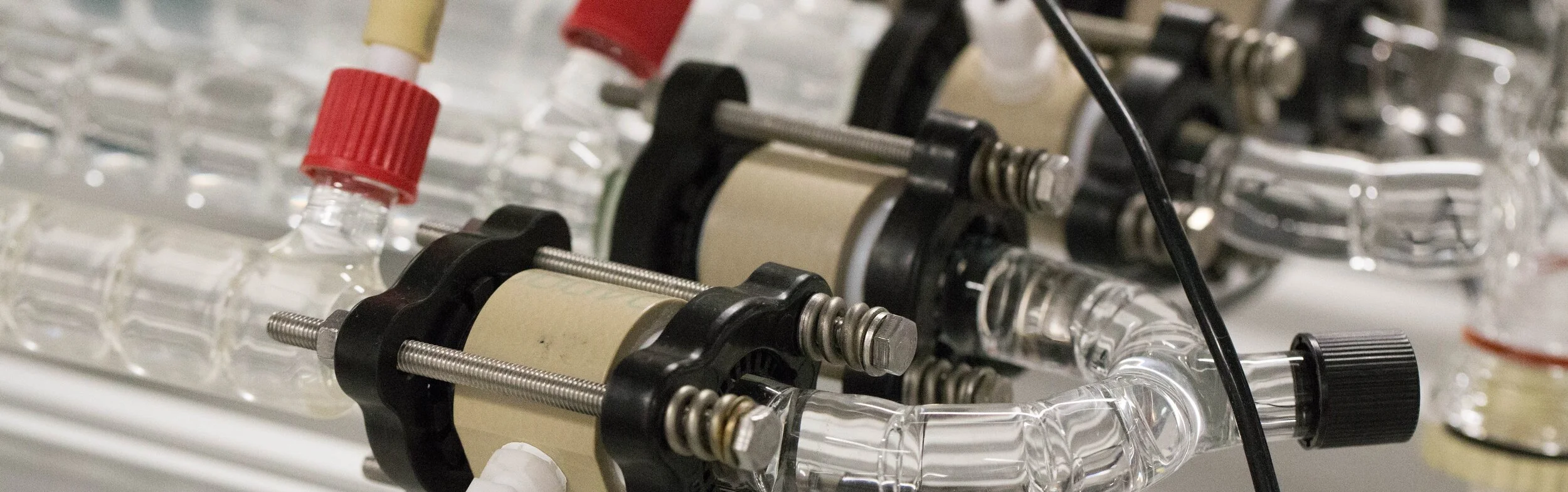

Developing Workflows for Continuous Crystallisation

Considerable time has been spent as part of the EPSRC CMAC CIM research campaign, designing and implementing a workflow for continuous cooling crystallisation.

Manufacturing Operations and Supply Chain Management Challenges in Continuous Manufacturing

This research explores possibilities to align future value network configurations and disruptive shifts in manufacturing and information technologies.

From Molecule to Lab to Plant: Computer Aided Process Design

Computer Aided Process Design (CAPD) and simulation tools have been successfully implemented in the chemical and oil industries since the early 60s to accelerate development and optimise the design and operation of process.

Exquisite Particles: Towards predicting agglomeration in APIs

Along with nucleation and growth, agglomeration is a commonly occurring process in crystallisation operations.

Made to Order Processing Plant

The “Make To Order Processing Plants” (MOPPs) project involving CMAC, CPI, AstraZeneca and led by Perceptive Engineering.

Platform Technology Development

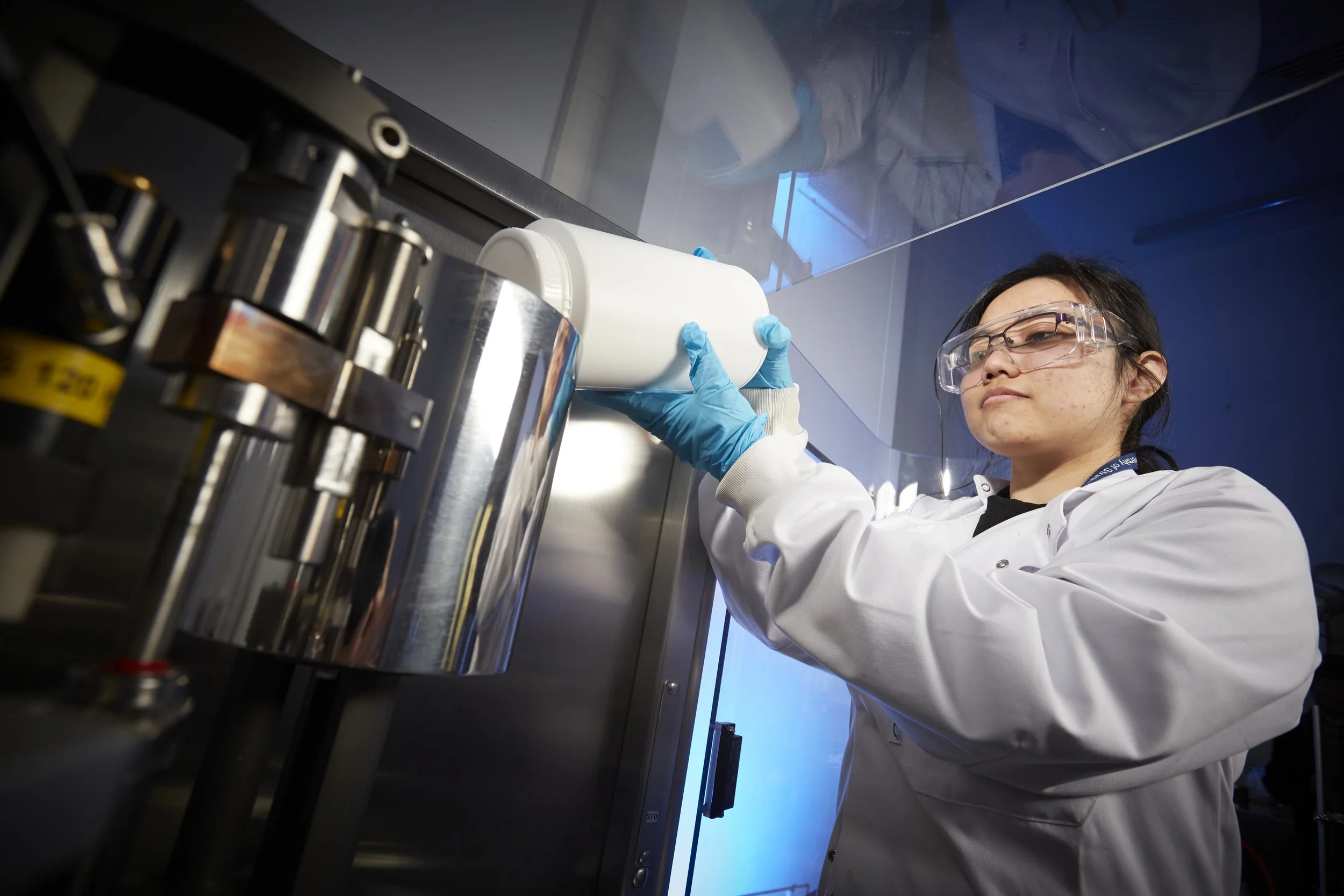

The particle engineering research group under the supervision of Prof Jan Sefcik has designed and investigated a novel continuous seed production unit.

Improved Manufacture of a Melt-Cast Explosive

In the production of many materials solid state variation is recognised as a key issue.

Solid State Selection Using a Novel Nucleator Coupled With Design of Experiment (DoE)

In the production of many materials solid state variation is recognised as a key issue.