ESTAN: A User-Friendly Toolbox for Improving Model Estimability and Predictive Performance

Background

Mathematical models have long been essential tools in science and engineering. They help researchers design chemical and pharmaceutical processes, assess risks, and optimise and control performance. With the rise of digital transformation, there’s a growing demand for more complex, high-fidelity models and digital twins that span multiple scales. Yet, many models fall short due to poor data quality, weak parameter estimation procedures, and inadequate model structures. These limitations often result in mathematical models with poor prediction capabilities, particularly in interpolation and extrapolation.

The Challenge

Current methods for analysing parameter estimates and model accuracy are fragmented and often require specialist knowledge in statistics, sensitivity analysis and numerical methods and applied math. Methods for assessing and maximising data information content are seldom applied. As a result, these methods are often overlooked and underexploited both in academia and industry, especially when time and expertise are limited.

The Solution

To address these challenges, researchers at Loughborough University in collaboration with CMAC’s Digital Manufacturing Research Centre, developed ESTAN, a user-friendly toolbox designed to help make complex modelling easier, even for those without modelling expertise and deliver mathematical models and digital twins with superior prediction capabilities.

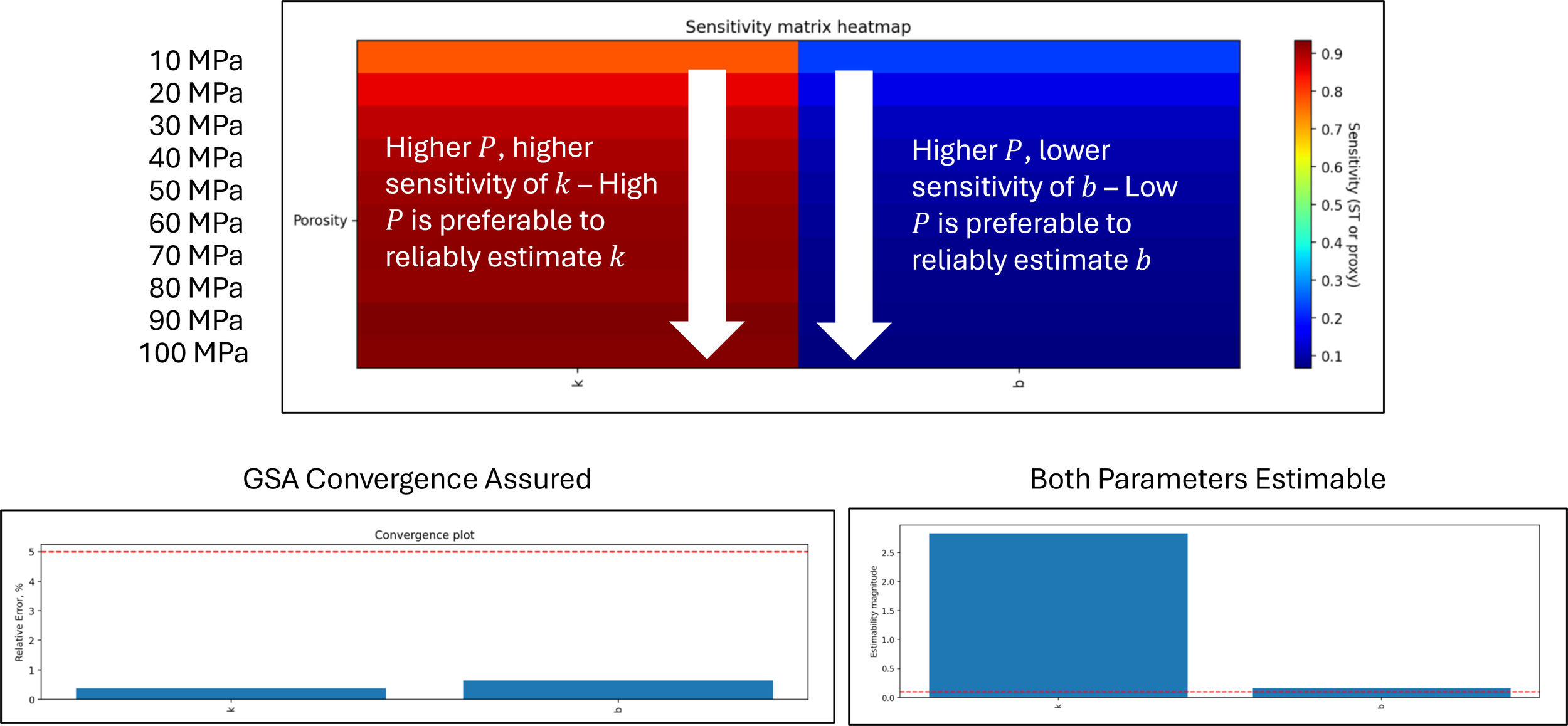

ESTAN offers unique capabilities to analyse data information content and reduce correlation amongst model parameters. The ESTAN toolbox applies different sensitivity analysis techniques, including Sobol or Fourier Amplitude Sensitivity Test (FAST), depending on the model's complexity and computational costs. A smart sampling is used to conduct effective sensitivity and estimability to help users improve the accuracy and reliability of their model predictions.

Validation

To validate ESTAN, the team applied it to three different case studies:

A non-dynamic Toth adsorption model - used to demonstrate how ESTAN handles simpler systems.

A dynamic batch cooling crystallisation model – used to show how ESTAN improves prediction accuracy in time-dependent processes.

A computationally expensive thermodynamic model - a computationally intensive model used to test ESTAN’s performance with complex, high-cost simulations.

In each case, ESTAN successfully assessed the data information content and identified the most estimable parameters, improved model reliability, and demonstrated its value in both academic and industrial contexts.

Impact and Benefits

ESTAN offers several key benefits:

· Accessibility: Designed for users with basic modelling experience.

· Efficiency: Saves time by automating complex analysis steps.

· Accuracy: Improves model predictions by focusing on reliably estimable parameters.

· Flexibility: Can be customised and extended by advanced users.

By simplifying a traditionally complex process, ESTAN empowers more researchers and engineers to build better models and make more informed decisions.

ESTAN has the potential to support a wide range of CMAC projects, from crystallisation and formulation to process control and optimisation. It could also be integrated into training programmes, helping to build modelling capability across academic and industrial partners.

As modelling continues to play a central role in digital transformation, tools like ESTAN will be key to unlocking the full potential of data-driven decision-making.

The research undertaken as part of this case study was conducted with funding from the Engineering and Physical Sciences Research Council (EPSRC), for Made Smarter Innovation - Digital Medicines Manufacturing Research Centre (DM²) at CMAC.