Made to Order Processing Plant

Academics:

Dr Ian Houson (Strathclyde)

Prof Alastair Florence (Strathclyde)

Researcher:

Dr Humera Siddique (Strathclyde)

Partners:

Perceptive Engineering, AstraZeneca, CPI, CMAC

The “Make To Order Processing Plants” (MOPPs) project involving CMAC, CPI, AstraZeneca and led by Perceptive Engineering, has the aim of designing a single, flexible control system software infrastructure and work process that will work across a whole range of equipment including reactors, crystallisers and spray driers. The same model predictive control system has been demonstrated on 1 continuous reactor (Corning Plate Reactor) at CPI and two continuous crystallisers (Nitech’s DN15 and Cambridge Reactor Design’s Rattlesnake) at CMAC. This case study will focus on the crystallisers.

The team has systematically developed a continuous crystallisation process for lactose from an existing batch process maintaining or enhancing the crystal attributes. The use of in-line PAT (IR, UV, FBRM, Raman etc) provides real-time information and feedback that the model predictive control system (see Figure 28) uses to control the process variables. A robust and reliable crystallisation system has been developed that has been run in continuous mode for over 5 days.

Key benefits from the project are:

Proven ability to run for 5 days and 26% higher yield (vs batch) in continuous crystallisation => improved yield

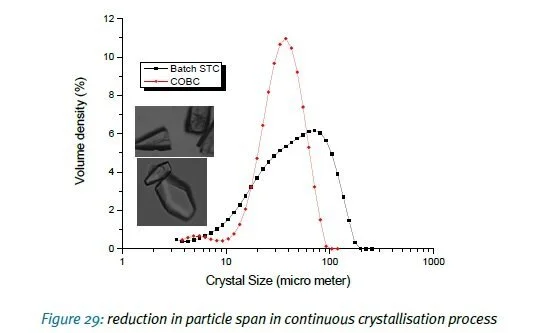

2 fold reduction in span of PSD vs stirred tank reactor => consistent & higher quality (Figure 29)

Reduction in Lactose crystallisation time from 16 hour to 5 hours => intensified process

Reduced manpower and waste requirements

‘Dial a Particle’ capability achieved (Figure 30)

Advanced process control capable of controlling available Crystallisation platforms

Full characterisation of the hydrodynamics of the batch and continuous equipment has enabled seamless transfer from batch to continuous processes. Shear has been shown to be a particularly useful scale-independent factor for transfer between equipment. Developing process understanding within a model predictive control environment has been shown to deliver real control and enhanced product characteristics over the equivalent batch process.

The project has been such a success that CMAC has commissioned Perceptive Engineering to install the control systems on 6 different platforms. Future research will focus on application of model predictive control to deliver consistent particles with variable raw material feeds as well as impurity rejection during crystallisations. The National Facility will provide access to these platforms and control systems for companies to test and evaluate novel processes.